Created through technology, driven by innovation

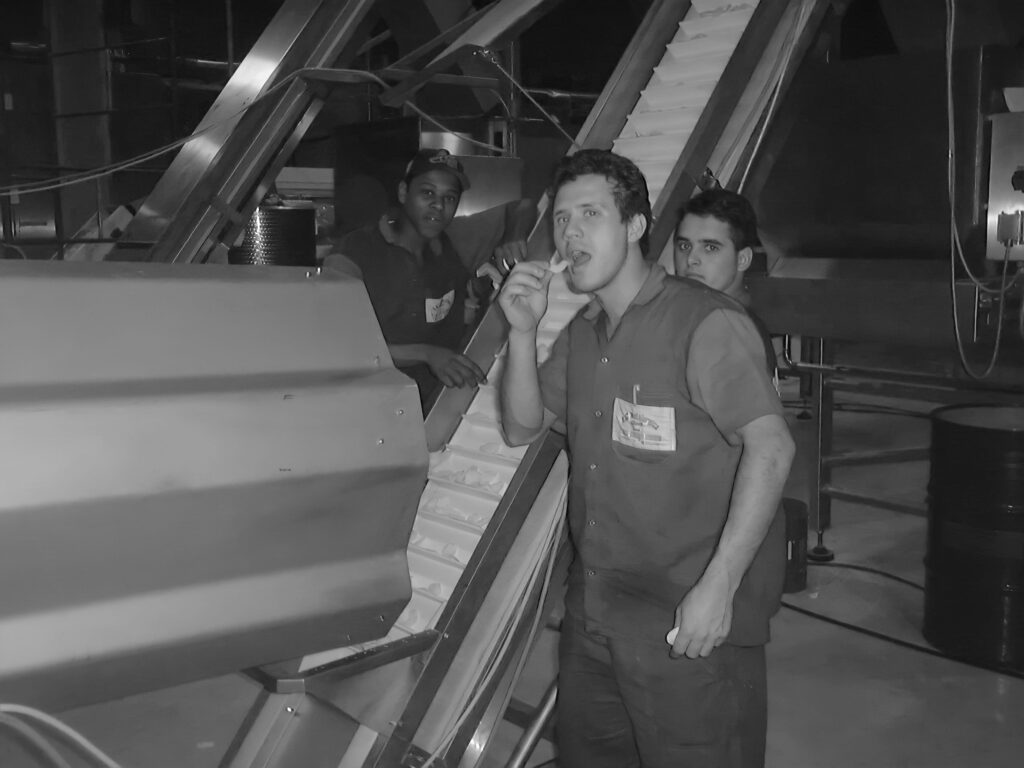

Since 1985, our company’s main focus has been and remains delivering quality solutions crafted to the client’s needs. At Kuipers, we believe in specialization, sustainable relationships and continuous development. Our team has found the optimal snack processing solution for small starters as well as large multinationals in over 60 countries.

Created through technology, driven by innovation

Since 1985, our company’s main focus has been and remains delivering quality solutions crafted to the client’s needs. At Kuipers, we believe in specialization, sustainable relationships and continuous development. Our team has found the optimal snack processing solution for small starters as well as large multinationals in over 60 countries.

countries

0

years

0

projects

0

Technology

Quality engineering, design and manufacturing are the base of our organisation. Our plants, many of which have been operating for over two decades, present snack producers with an efficient and long-term solution crafted specifically for their production needs. Engineered and manufactured locally in the Netherlands.

Innovation

Engineering excellence does not come without innovation. Internally and together with our customers, we aim to solve new and old problems in a different way. Our frying systems are known worldwide to be some of the most advanced, particularly the peanut processing machinery. This presents our clients with huge yearly costs savings.

People

Our small team, some of which have been with us for over a decade, focuses on continuous development not only in terms of equipment but relationships with the stakeholders. We remain at base a snack machinery engineering expert with focus on the producers’ needs.

Service

Our machinery’s lifetime is in the majority of cases more than 10 years. During this period and after, our service and aftersales teams are there to ensure continuity and efficiency of the line, advice on upgrades and supply all the necessary extras for you to continue producing optimally. Remote assistance and on-site visits.

Delivering quality since 1985

-

1985A food processing engineering expert begins small as a consultant sharing his knowledge within the industry.

-

1987Began first designs and manufacturing of in-house frying systems to produce pellets snacks.

-

1985-1995First pieces of equipment sold were conveyor belts most of which in Belgium and the Netherlands.

-

1995Began sales outside Europe, mainly in the Middle East, with a small pellet snack plant sold in Kuwait.

-

2005After 20 years of operations, Kuipers was present in over 35 countries with varied technology for pellet snacks, nuts, potato chips, corn nuts and more.

-

2019New management, new strategy and long-term focus.

-

2020Presenting the most advanced frying technology, particularly for nut processing. Testing and proving the lowest frying oil turnover time for peanuts.

-

2021A complete upgrade of our French fries processing plant enabling Kuipers to deliver turnkey systems from raw potato input to freezing, 1 to 5 ton per hour output.

-

2022Further development of Kuipers battered or coated crispy onion line. Due to high demand, we have developed larger capacity lines for crispy onions.

-

2022Development and delivery of our energy recovery and odour elimination unit. This technology is great for applications where the input contains a high level of moisture, for example, potato chips.

-

2024Acquiring Lalesse Extrusion and expanding our snack production equipment portfolio with turnkey extrusion plants. Technology includes mixers, single screw extruders, dryers and flavouring systems.

-

2024Together with SV Agri, founded Krispfood. A quality solution supplier for competitive prices specifically created for the Indian market.

countries

0

years

0

projects

0